UGA researchers are working to produce faster-growing sweetgum trees by growing embryogenic sweetgum cultures in bioreactors, computer-operated systems used for growing cells under controlled conditions.

“Most people think to get more trees, you just collect seeds and plant them,” said Scott Merkle, a professor of forest biology in the Warnell School of Forestry and Natural Resources. “We’re actually making trees from the cells that grow in our cultures.”

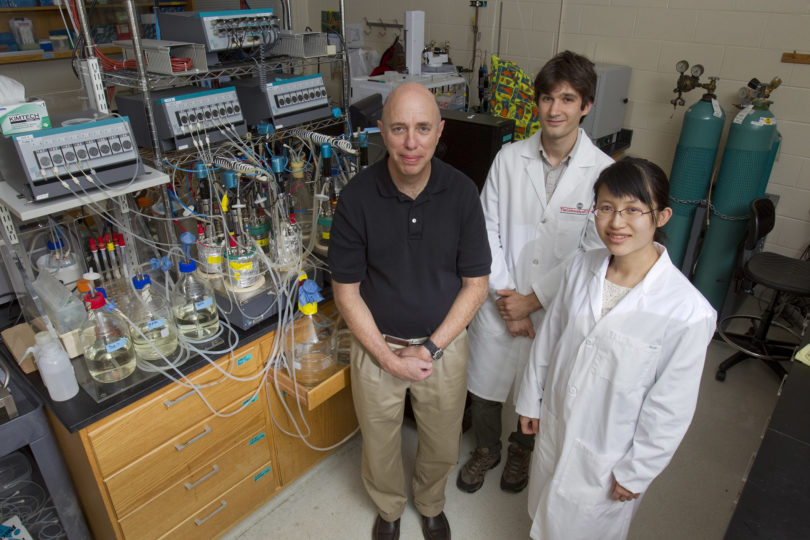

Merkle is assisting one of his graduate students, Siran Lu, with this project. Lu is using plant cell culture techniques to clone the cells of an artificial hybrid inside bioreactors.

“What I’m doing now is trying to improve sweetgum production through different steps of the process,” Lu said.

She is using three different kinds of bioreactors to see which will produce the most plant cells at the fastest rate. Each bioreactor contains liquid media that is a mixture of fertilizer, sugar and other nutrients that plant cells need to grow.

After the embryogenic cells are grown, they can be used to make embryos, which then are germinated and potted for planting. Merkle said the traditional method of growing trees limits researchers’ knowledge about how the trees will grow.

“Planting a seed makes one tree but you don’t know whether it will turn out to be a great tree or not,” he said.

Merkle said cloning the trees by developing embryos allows researchers to accurately test the quality of the trees. The cloned embryos can be planted and field-tested for growth rate and quality within three to five years.

This tells researchers which cloned seeds will make the best trees and then they can make more trees with the same desirable traits. The culture can be stored in liquid nitrogen and kept in a cryogenic freezer until researchers want to use it.

Merkle said the ultimate goal is to produce strong, high-quality trees that can be used for biomass energy in short rotation plantations or for pulp and paper.

Lu also uses a one-liter system bioreactor located at the Franklin College of Arts and Sciences Bioexpression and Fermentation Facility.

She and Merkle said they would not have been able to sufficiently conduct their research without the fermentation lab’s equipment and personnel expertise.

“It happened to work out well and they’ve just been really, really helpful to us,” Merkle said.

One of the lab’s fermentation scientists, Paul Volny, said the collaboration has been helpful for BFF as well. The BFF was able to gain experience with plant cell culture, a rare occurrence at the lab, which may now potentially be a service for a future client.

“By using our one-liter bioreactors they have more capability to control and monitor the culture conditions that they would not otherwise have,” Volny said.

The Bioexpression and Fermentation Facility is a core facility that offers equipment use and expertise to UGA faculty and students in addition to doing contract work for outside companies. It is part of the department of biochemistry and molecular biology and is headed by David Blum, director.

Lu’s project was funded by ArborGen Inc., a commercial forestry company headquartered in South Carolina. The project is part of her master’s thesis, which is scheduled for completion in 2014.